How space refrigerators are reshaping vaccine delivery and food transportation?

Since the historic Shenzhou-8 mission in 2011, China's space refrigerators have soared beyond Earth to become an integral part of the country's manned space missions. This groundbreaking achievement shattered the long-time technological monopoly held by foreign nations, positioning China as the third country, following the US and Russia, to master the core technology of space refrigeration.

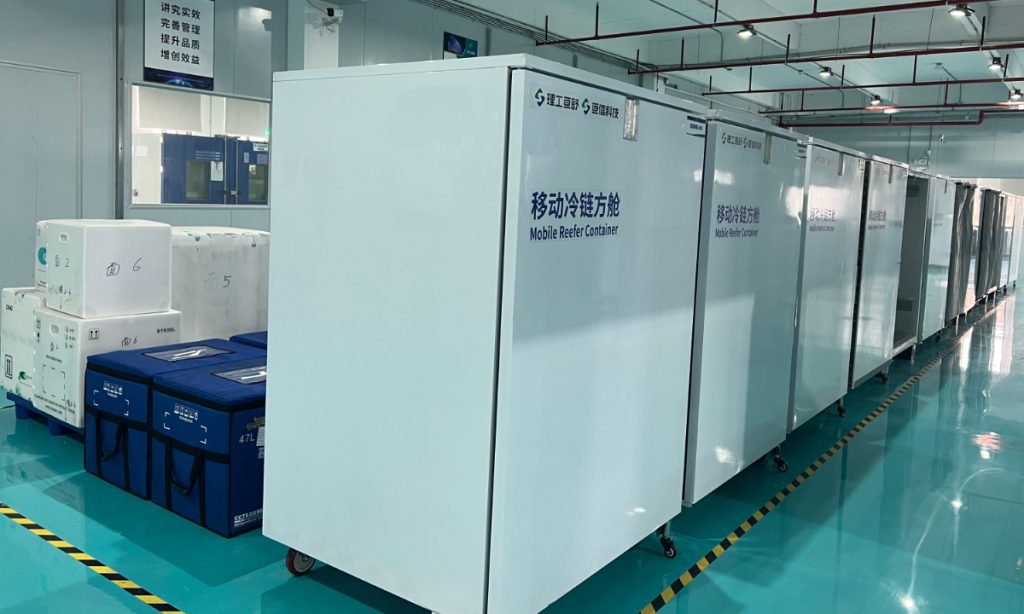

In an industrial park in Foshan, South China's Guangdong Province, the local government has harnessed cutting-edge aerospace technology to propel the development of intelligent medical refrigerators and cold-chain logistics, which has become a new engine driving economic growth in the region.

Specifically designed for space

What's special about refrigerators used in space is they're specifically designed for the space environment, allowing them to serve unique purposes compared to household refrigerators.

Given the highly specialized nature of the space environment, space refrigerators boast unparalleled performance that set them apart from traditional household models. In the microgravity environment of space where objects float, stability and convenient access must be ensured, analysts noted.

For one thing, manned space missions demand exceptional precision down to the gram, and that requires space refrigerators to be much lighter than household ones. Moreover, during the rocket launch phase, the Shenzhou spacecraft is subject to various extreme challenges such as vibrations, impacts, and noise, necessitating space refrigerators to be more stable and possess stronger structural integrity capable of withstanding momentary maximum accelerations of 12g for vibrations and 500g for impacts. This is equivalent to space refrigerators enduring instantaneous impacts 500 times their own weight.

Additionally, taikonauts in space need to handle multiple tasks at the same time. To lighten their workload, space refrigerators need to incorporate Internet of Things technology, so that taikonauts can control power on/off, temperature settings, and other operations using a handheld terminal similar to a PAD, a solution not even present at the International Space Station.

Combining these designs in medical coolers and cold-chain logistics, the local government of Foshan city's Nanhai District has successfully developed a series of technologies for multi-usage refrigerators as part of the "National Major Instrument Development Project," including low-power, high-efficiency refrigeration, high-density phase-change energy storage, intelligent temperature control, temperature distribution, and cold storage and insulation under extreme conditions.

The technology transfer of "space refrigerators" has demonstrated its effectiveness in Guangdong Province, aiding in addressing issues related to the last-mile delivery, monitoring, and management of vaccines and food transportation, the Global Times learned from the project manager.

Outstanding benefits

According to the smart cold storage system developer Genshu (Guangdong) Technology Co., Ltd., traditional cold storage facilities have a number of drawbacks such as high costs for energy, difficulty in maintaining a constant temperature, and the need for multiple transfers between warehouses during transportation due to their large sizes. In contrast, the smart cold storage system offers several benefits.

By leveraging intelligent manufacturing and aerospace technology, this system provides an innovative and advanced solution for cold-chain logistics for medical supplies such as vaccine.

For one thing, it allows for flexible sizing according to specific needs and eliminates the need for on-site construction. The system also offers significant cost savings compared to building and maintaining large cold storage facilities, Deng Yulin, founder of the company who is also a professor in the School of Life Sciences at the Beijing Institute of Technology and member of the International Academy of Astronautics (IAA), told the Global Times.

Each compartment of the refrigerator is equipped with information pallets that record all necessary data, including the items in store, temperatures and quantities, making it easier for transportation personnel to track and manage goods, Deng said.

Cloud monitoring further enhances control and transparency by providing real-time information about the location, handling, and opening of the containers.

Another key advantage of the system is the ability to maintain a consistent temperature throughout the transportation process.

Space materials are also used for weight reduction in the cold storage devices, meanwhile ensuring that different locations within the device can maintain the same desired temperature with minimal variation. "The technologies we have applied on these cold-chain storage units are even more advanced than those we use in space, as they have been remodeled to suit ground conditions," Deng told the Global Times.